Technical Articles

10.06.20

Effect of floor surface regularity on robots

In this rapidly changing world, automated warehouses are becoming increasingly more common. Spurred on by the growth in ecommerce and our demand for faster and faster delivery times, companies are employing Autonomous Mobile Robots (AMRs) to store and retrieve product. A popular system known as P2P or pick-to-person, uses small robots to ferry around pods or mobile shelving units from a storage area to a picking station.

On the face of it, you wouldn’t consider the surface regularity requirements of floors for these AMRs to be too demanding. After all, the total height, including the pod they carry, is only in the order of a couple of metres tall. However, the geometry and manner in which these vehicles operate is significantly different to that of a fork-lift or VNA truck.

Configurations of robotic systems vary widely. While some run in a free movement pattern, many operate on a strict grid. Operating speeds of the latter can be significantly faster. A typical P2P robot consists of a centre drive axle and four castor wheels – one at each corner. To pick up a pod, the robot rotates around its axis in a corkscrew fashion. This not only imposes certain conditions on surface regularity, but also characteristics such as gloss, surface roughness and abrasion resistance.

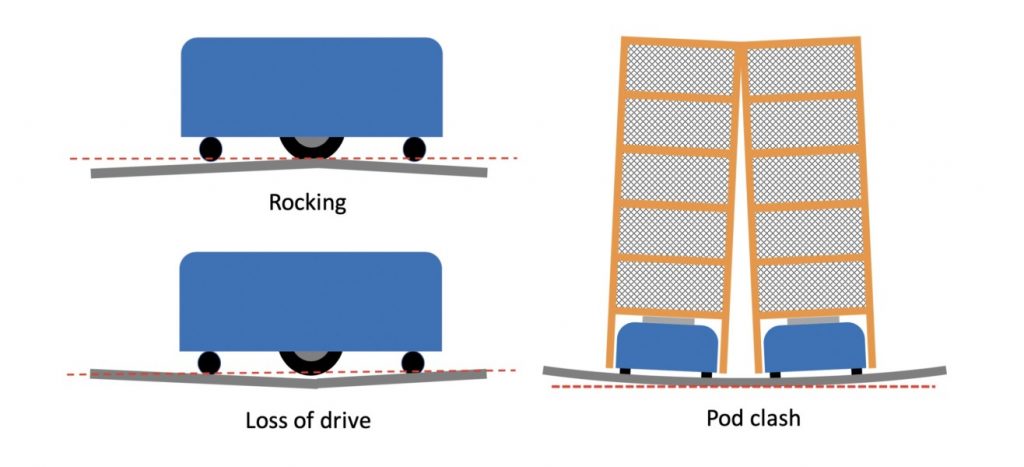

In terms of surface regularity there are two particular cases that create problems with the smooth running of these robots. These are concave and convex curvature, which can be defined as rate of change error over a short and/or medium wavelength. In the case of a convex error, the vehicle is no longer supported by the castor wheels which induces rocking about the centre axle. For concave errors, the centre axle can become suspended and lose drive. Over a greater wavelength, concave errors can lead to clashes between vehicles running parallel to each other.

At Floor Dynamics, we have developed technology to produce High Definition mapping of the entire floor surface, speeding up the construction of the floor and the commissioning of the robot system.

Andrew Keen – CSO RCR Flooring Services