Technical Articles

10.06.20

Floor surface regularity terminology – what does it mean?

“There is no point in being precise when you don’t know what you are talking about.” – John Tukey

Whether due to lack of technical knowledge, or intent to confuse, there is much confusion over the terminology used in the industrial flooring industry. We often hear the term flatness used interchangeably with the correct term of surface regularity. Flatness, like levelness, is a specific property of surface regularity, in this instance, referring to the short wavelength variation of the surface. Operators and owners of buildings often talk about wanting a superflat floor. This is a very ambiguous term and has been used to mean many things. Today, it is generally accepted within the industry as representing the highest classification required for VNA systems. A more appropriate definition, or specification, would be Concrete Society TR34 4th Edition DM1 or ASTM E1486 Fmin100. The danger is, this classification of floor would actually be detrimental if wrongly specified for the majority of uses, where traffic would be crossing perpendicular to construction joints.

Then we come to the specific language used around the subject of measurement. Such words, when sprinkled into a conversation, can sound very clever. They are often used to justify just how good one company, or method is in comparison to another – especially when it comes to using proprietary equipment for surveying. Cynically, it could be viewed that certain quarters of the industry wish their black boxes to remain closed and free from scrutiny. For many years, sophisticated commercially available equipment such as total stations, digital levels and laser scanners have been used in the world of surveying. It is the use of these measuring devices, that offer us the opportunity to look at surface regularity requirements for industrial flooring in a more appropriate way. A true understanding of terms such as those below, is still required.

- flatness

- levelness

- waviness

- reference to datum

- superflat

- defined movement

- free movement

- tolerance

- accuracy

- resolution

- precision

- repeatability

- confidence limits

- uncertainty

Let’s consider three key characteristics of measurement – accuracy, precision and resolution.

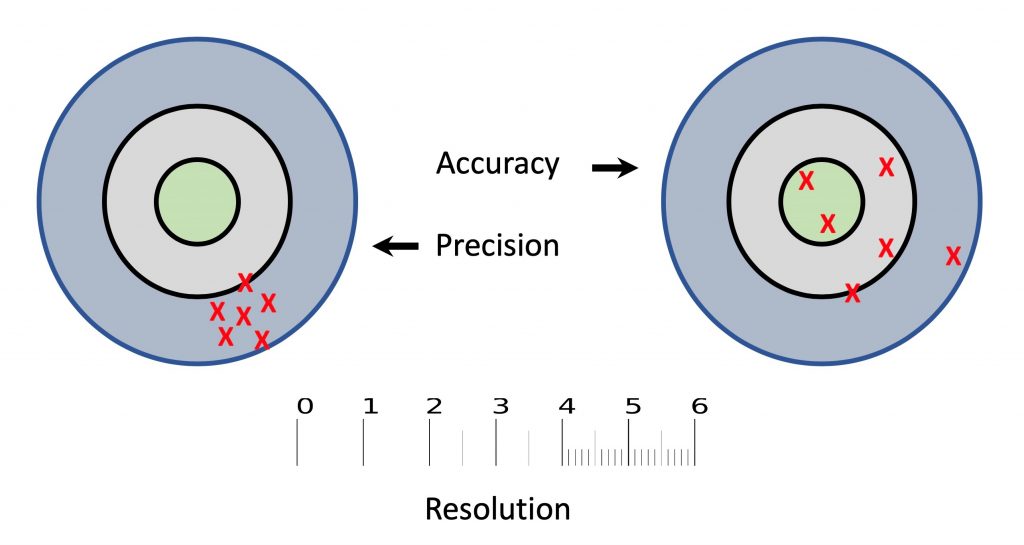

Although almost universally used interchangeably, something being accurate or precise are two completely different properties. Consider taking six shots at a target, one of the examples above demonstrates accuracy. The other, precision.

Accuracy can be defined as closeness to target, or closeness to truth. Precision, however, is a measure of repeatability. The target shown on the left demonstrates precision. The rifle sight used in the instance can be calibrated slightly up and to the left. At which point, all shots would hit the bullseye. The example on the right, however, demonstrates that it is possible to get a bullseye, but perhaps there is also an element of luck. This “luck” would be expresses as confidence.

Resolution is the smallest distance that can be measured without ambiguity. It is the number of intervals there are between major measurement markers. In order to measure something with certainty, the resolution is typically one decimal finer than the result required. Using the example on the slide, a point place somewhere between the 2 and 3 could only be expressed with certainty to 0.5. For example, a point at approximately 2.3cm could only be quoted with certainty to be between 2 and 2.5cm. Only when there the resolution show mm markings, could it be determined that the point is either between 2.4-2,5cm or 2.5-2.6cm. It still couldn’t be stated at 2.36cm.

Just because a tape measure has a resolution in mm, it does not mean that it is necessarily accurate. To state this with confidence, the tape measure needs to be calibrated against a known version of the truth.

Why is all of this so important? With the increasing adoption of autonomous materials handling equipment in logistics centres and manufacturing facilities, different demands are being placed on industrial floors. This requires that we expand our understanding of the behaviour of vehicular traffic on floor surfaces. Concrete consists of a bunch of naturally occurring materials mixed by a batch process, yet at times, we expect results that you would get from machined metal. Using more science and less art, we will ensure that this very versatile material will continue to provide the solution to changing demands.

Andrew Keen – CSO RCR Flooring Services